STS Enhancement Products

LCD Touch Screen Monitor

LCD touch screen and system input signal into a single unit to replace heavy CRT monitor and light pen on the AMAT(Applied Material Inc.) semiconductor systems seamlessly. Compatible with Centura, P5000, PI9500, and Endura systems. 60% reduction in power utilization. 90% package size reduction. Increased screen luminescence. Lighter and thinner than CRT,increasing mobility. Longer life time than CRT monitor. The steel frame module provides high integration and durability.

Hard Drive with RAID Array Conversion

Features - Slim Size: External dimension is as the same as the hard disk drive. Plug & Play: No additional driver or software requirement. Compatible with any current brand and capacity hard drives as along as the drives meet standard SATA spec. Comply with any standard SCSI interface at he host end. The most cost effective solution.

Floppy Drive Upgrade, Compact Flash

SCSI to CF Floppy Emulator Slim and Light, exterior dimension equals to a floppy disk drive. Plug and Play, compatible to the original system, no additional adapter required, no software change and install onto system. Easy-configuration, Increase access rate of system

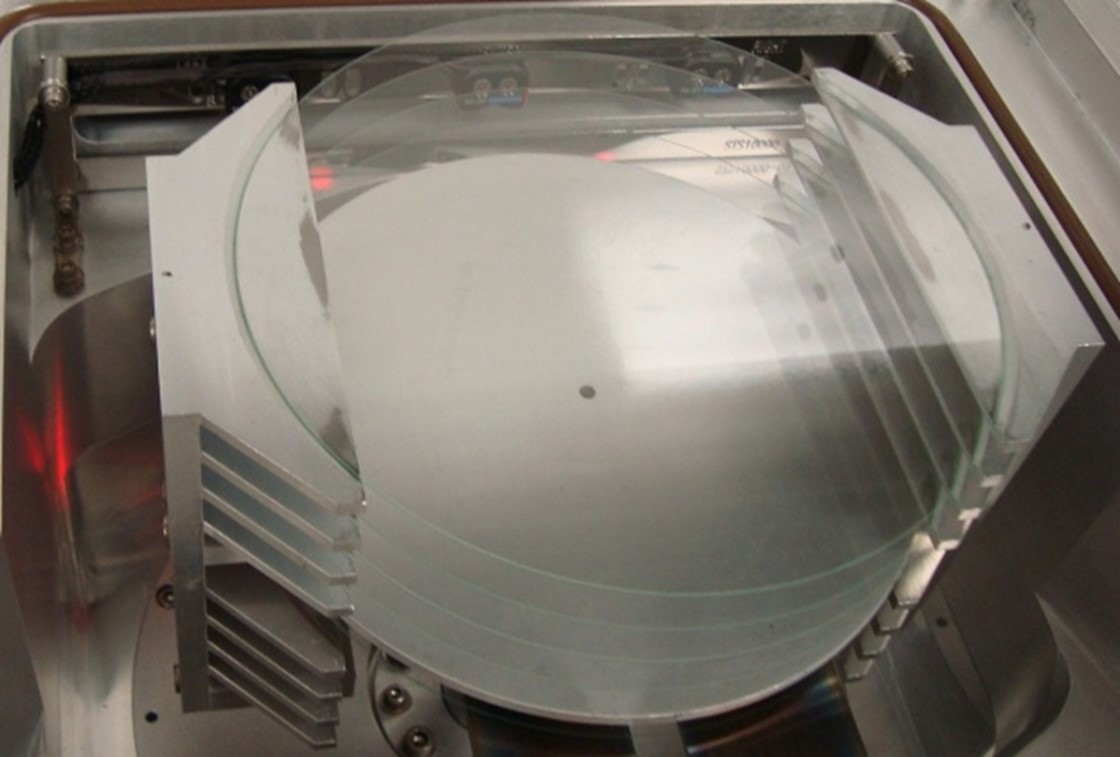

P5000 Centerfinder Upgrade

We offer a replacement to legacy Applied Materials ® centerfinder board with our fiber optic centerfinder board allowing the system to detect: • Quartz • Glass • Sapphire • Gallium Arsenide • Aluminum Oxide • Silicon Easy installation