MxP

Applied Materials Mxp Etch Chamber

Are you looking for an advanced etch chamber solution?

The Applied Materials MxP Etch Chamber is designed to deliver reliable, high-quality etch processing for a variety of applications. This chamber offers a range of process options, enhanced performance features, and other benefits to help you achieve the results you need.

With the MxP Etch Chamber, you can optimize the etch process to achieve the desired results for your specific application. Let’s look at the features and benefits of this advanced etch chamber to help you decide if it’s the right solution for you.

Overview of the MxP Etch Chamber

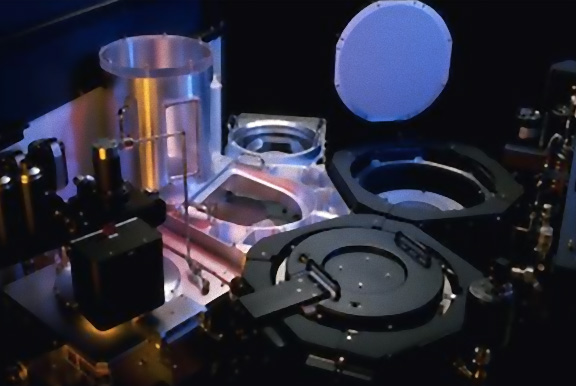

The MxP Etch Chamber is a powerful tool used in the semiconductor industry. It’s a type of etch chamber, which can remove material from a surface using a chemical reaction. The MxP uses plasma to create a reactive gas that etches away the desired material. This is a great tool for creating precise and intricate designs.

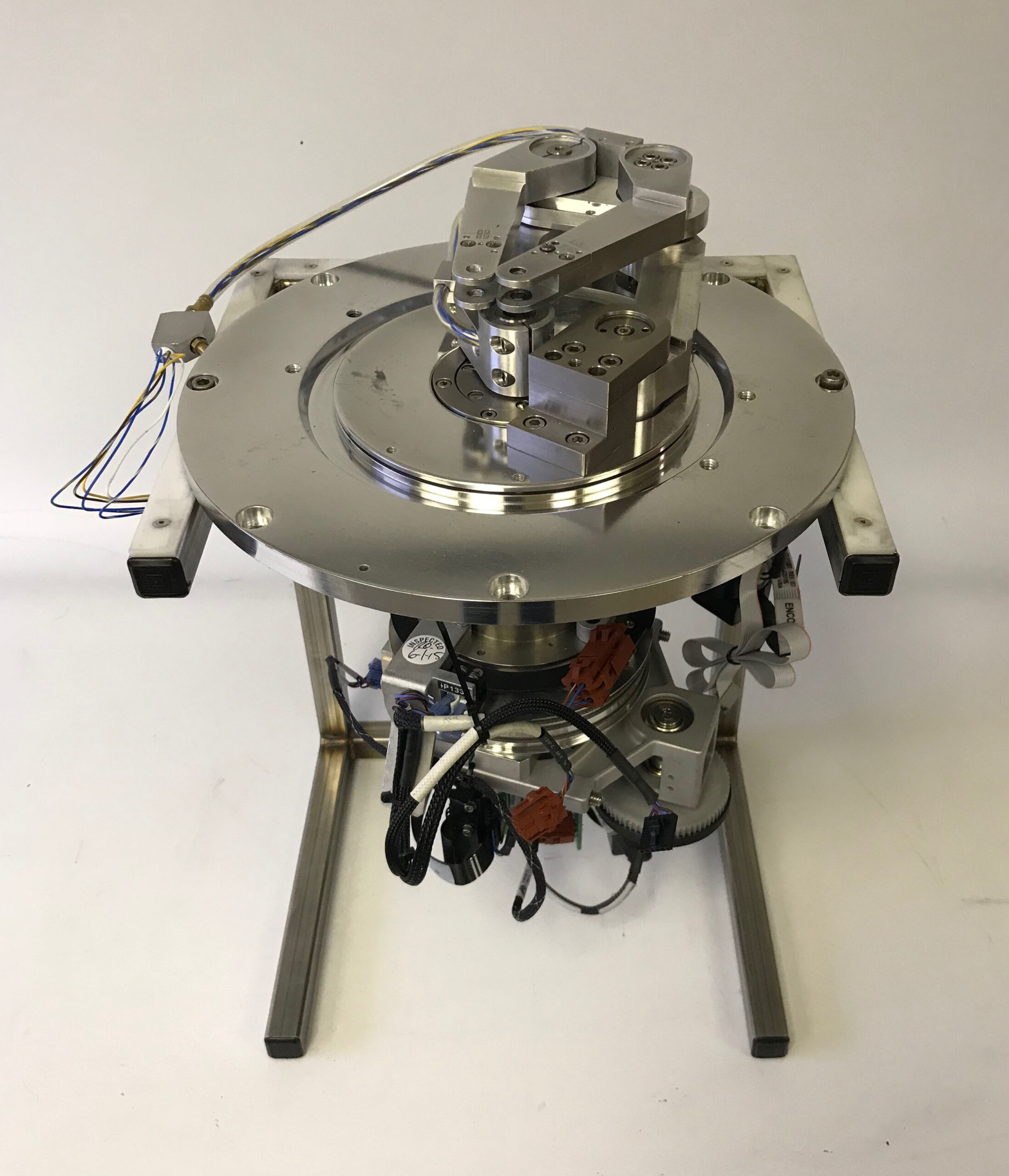

The MxP has a few unique features that make it stand out from other etch chambers. The first is its multi-axis capability, which allows it to move in multiple directions at once. This allows it to etch more complex shapes than other machines. Additionally, the MxP’s advanced software allows for precise control over the etching process. This ensures that the etching is done with extreme accuracy.

The MxP also has a few safety features that make it safe to use. It has an automated shutoff system which will turn off the etching process if an unsafe situation arises. This helps to protect the operator and the environment. Additionally, the MxP is equipped with a built-in gas delivery system which ensures that the right amount of gas is used for the etching process. This helps to ensure that the etching is done correctly and safely.

The MxP is a powerful and versatile tool that can be used to create complex designs with extreme precision. It is a great tool for the semiconductor industry and is used in many different applications. With its advanced features and safety features, the MxP is a great choice for those looking for a reliable etch chamber. With its capabilities, it is sure to become an invaluable tool for many years to come.

Benefits of the MxP Etch Chamber

You’ll benefit from the powerful etching capabilities of this chamber! The MxP Etch Chamber is an advanced technology that offers a variety of features and benefits.

It is designed to provide precise etching capabilities in a cost-effective manner. The chamber is designed to be easy to use and operate, with intuitive controls and a variety of safety features.

It is also designed to be highly efficient, allowing for faster etching times and higher throughput. The chamber also offers excellent uniformity and reproducibility for the etching process.

The MxP Etch Chamber is also designed for high-performance etching, with an advanced design that provides excellent control over the etching process. The chamber is designed to minimize the time required for etching and to ensure the highest quality results.

It is also designed with a variety of features that allow for precise control over the etching parameters. This ensures that the etching process is consistent and repeatable.

The MxP Etch Chamber is also designed for consistency and reliability. Its advanced design ensures that the etching process is consistent and repeatable, even over long periods of time.

This ensures that the etching results are reliable and reproducible. Additionally, the chamber is designed with a variety of safety features that ensure that the etching process is safe and secure.

The MxP Etch Chamber is a powerful and cost-effective tool for etching materials. It provides excellent etching capabilities, with precise control, uniformity, and repeatability.

It is also designed for high-performance etching, with an advanced design that ensures consistent results over long periods of time. With its intuitive controls and safety features, the MxP Etch Chamber is an ideal tool for etching applications.

Applications of the MxP Etch Chamber

The MxP Etch Chamber has a wide range of applications. It can be used for creating micro-patterns in semiconductor chips and etching the grooves of a compact disc. It is also used for producing nano-scale structures like nanowires and creating three-dimensional structures with layers of different materials.

The chamber’s design allows for fast etching times and high-precision control over parameters such as temperature, pressure, and gas mixture. It can etch a wide range of materials, including metals, semiconductors, and dielectrics. The chamber also allows for the simultaneous etching of multiple layers of different materials, reducing time and cost.

The chamber’s design also allows for the integration of different etching techniques, such as dry and wet etching. This makes it more efficient and versatile, allowing for the etching of different types of materials with a single tool.

Furthermore, the chamber’s design allows for the integration of other processes like ion implantation and deposition. This streamlines the fabrication process, reducing steps and increasing production times.

The MxP Etch Chamber is highly reliable and cost-effective. It can be used in various working environments and is easy to maintain and upgrade, minimizing downtime and increasing productivity.

In conclusion, the MxP Etch Chamber is an efficient and versatile tool for etching various materials. Its precise control and high-performance results make it a popular choice for many etching processes.

Process Options Available

The MxP Etch Chamber offers a variety of process options for your etching projects. You can choose between single- or multi-wafer etching, deep or shallow etching, and etching of small or large areas. This allows you to customize the etch process to meet your specific requirements.

The MxP Etch Chamber utilizes a reactive ion etching process to etch a variety of materials, including metals, polymers, and ceramics. This process creates a precise etch pattern with a high degree of uniformity, making it ideal for a variety of etching applications. The chamber can be used for both wet and dry etching processes, giving you a wide variety of etch results.

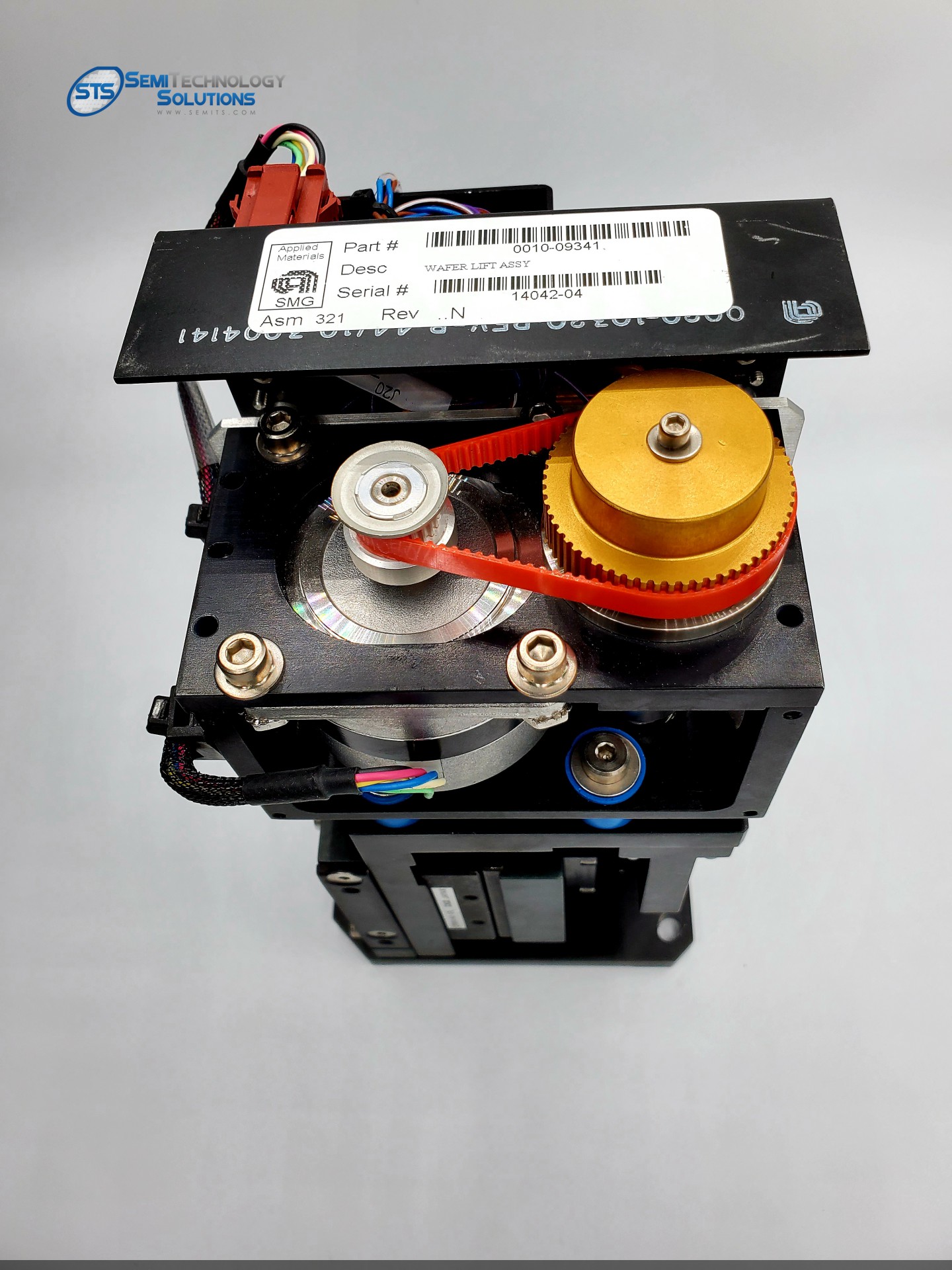

In addition to its versatile process options, the MxP Etch Chamber is easy to use and maintain. It features a user-friendly touch-screen interface that allows you to easily set up and monitor the etching process. The chamber also comes with automated features, such as a gas control system, a vacuum pressure control system, and an automated wafer handling system.

With the MxP Etch Chamber, you can achieve accurate and precise etching results. Its wide range of process options allows you to customize your etch pattern to meet your individual needs. Plus, the chamber’s user-friendly interface and automated features make it a convenient choice for a variety of etching projects. Unlock a world of possibilities for your etching projects with the MxP Etch Chamber.

Enhanced Performance Features

Experience enhanced performance features with the MxP Etch Chamber. It is designed to deliver unmatched performance in etching applications, with a two-stage etching process for faster etching times and improved accuracy and precision. The chamber also features an advanced pressure management system that ensures consistent pressure throughout the etching process, reducing errors and improving etch quality. Additionally, it offers customizable etching parameters to tailor the process to your specific needs.

The MxP Etch Chamber also prioritizes safety. It is equipped with an electric interlocking system that automatically shuts off the system when the safety door is opened, reducing the risk of operator exposure to hazardous chemicals. The chamber also has an advanced filtration system to minimize the release of fumes and odors during etching.

In terms of monitoring and control, the chamber is equipped with a digital display for real-time monitoring and control of the etching process. This helps reduce the risk of errors and ensures consistent results. Furthermore, the chamber has an automatic calibration system to maintain the accuracy and precision of the etching process.

Overall, the MxP Etch Chamber provides an efficient and reliable etching solution. Its advanced performance and safety features make it ideal for any etching project. With its monitoring and control features, you can expect accurate and precise results with minimal effort. Take advantage of the enhanced performance and safety features of the MxP Etch Chamber for your etching projects today!

Conclusion

The Applied Materials MxP Etch Chamber offers numerous benefits that make it the ideal choice for your etching needs. With its enhanced performance features, multiple process options, and wide range of applications, the MxP Etch Chamber delivers reliable and efficient results. No matter what your requirements may be, you can trust the MxP to get the job done quickly and effectively. Upgrade your etching capabilities with the MxP Etch Chamber today.